- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

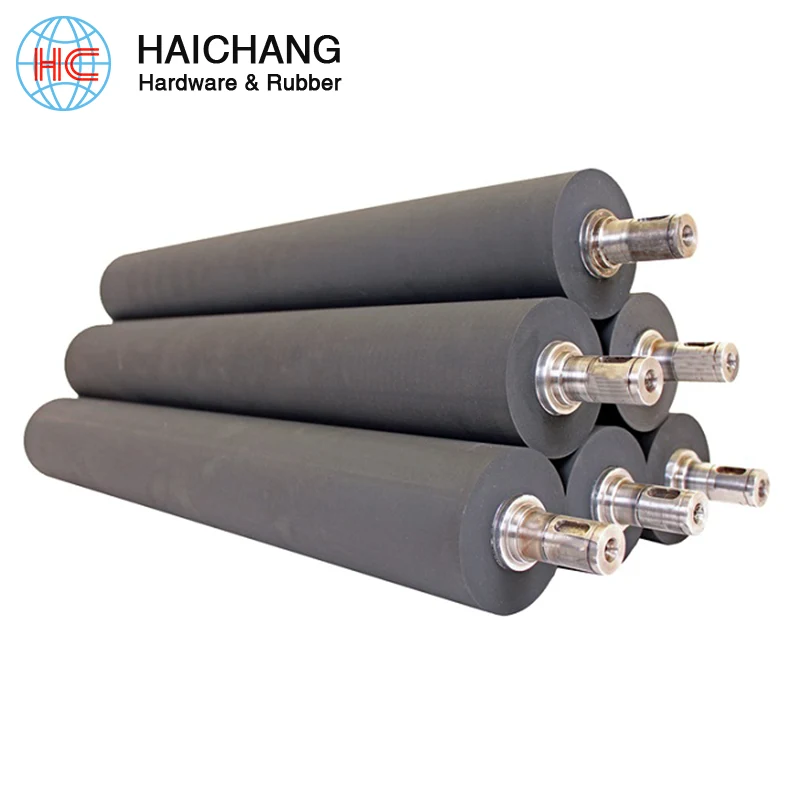

High Temperature Resistant Silicone Rubber Rollers

You can rest assured to buy High temperature resistant silicone rubber rollers from our factory. Haichang serves a variety of industries using silicone rubber rollers as well as Viton and HNBR overlays. These covers are used in rubber roller applications requiring high temperature performance and high release capabilities, areas of specific chemical resistance, or high temperature abrasive applications.

Send Inquiry

As a leading manufacturer of High temperature resistant silicone rubber rollers, our key features include excellent heat resistance, mold release characteristics, and a smooth surface finish. These rollers eliminate the need for glue or other adhesives, offering convenience in application. With a vast size range available, including silicone foamed rollers, we cater to various needs. Our rollers are offered in both food-grade and industrial commercial grades, showcasing a wide functioning temperature range. Known for their exceptional durability and resistance to tearing, our silicone rubber rollers ensure reliable performance in diverse applications.

Our service

Cut to size

On-time Dispatch Guarantee

Customize the size, thickness, color, hardness as you need

Heat Resistant Silicone Rubber Roller

We are a professional customized heat resistant silicone rubber roller manufacturer in China. High temperature resistant silicone rubber rollers is a specialized equipment used for heat transfer. It is made of silicone rubber with good heat resistance and can be used for a high temperature environment for a long time. The rollers have a smooth surface and can withstand temperatures up to 300 degrees Celsius. They are also non-stick, so they do not transfer heat to the material being rolled.

In addition, they are extremely durable and have a long service life.

HaiChang is a manufacturer specializing in High temperature resistant silicone rubber rollers. There are many factors to consider when deciding which heat resistant roll is right for you. The first is the temperature range. Some rollers are designed for high temperatures, while others can withstand lower temperatures. You also need to consider the size of the roller. Another factor to consider is the type of surface you want to use the roller on. Finally, you need to decide how much force you need the roller to exert. We welcome your inquiries and look forward to serving you!