- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

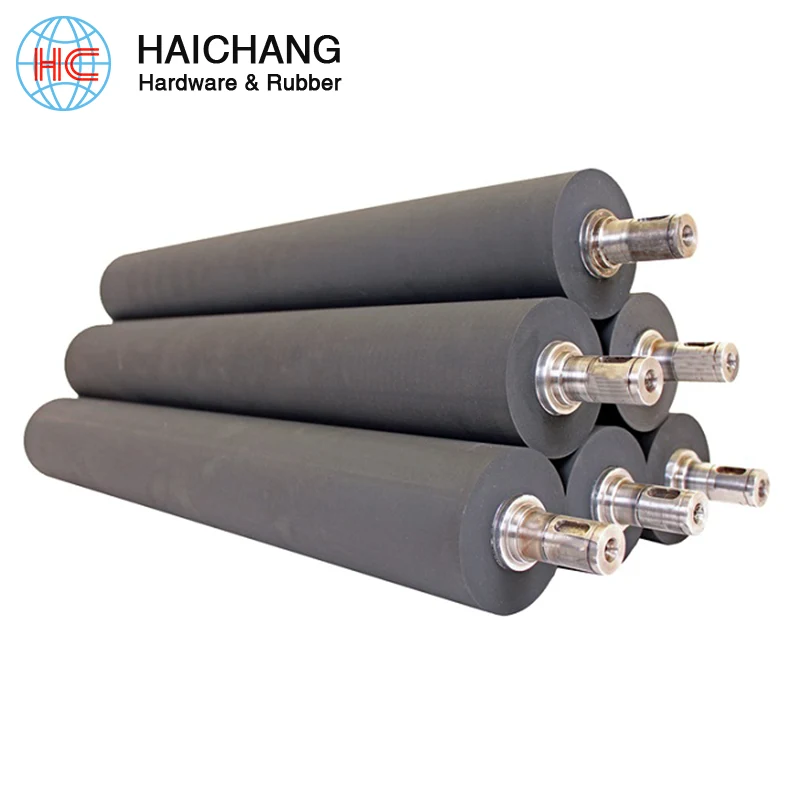

Nitrile Rubber Roller

Haichang is Nitrile Rubber Roller manufacturers and suppliers in China who can wholesale it. These rollers exhibit excellent properties such as oil resistance, aging resistance, and corrosion resistance. Customization options are available for both size and color, allowing for tailored solutions to meet specific needs and preferences.

Send Inquiry

We are manufacturers of high-performance and durable synthetic nitrile rubber roller sleeves with excellent oil, alkali, water and abrasion resistance. Nitrile Rubber Roller (NBR), commonly known as Buna-N, represents a high-quality, commercially blended rubber renowned for its moderate resistance to both synthetic and natural oils and greases. Characterized as a versatile general-purpose rubber, NBR offers an outstanding equilibrium of physical and chemical properties. Noteworthy for its good wear resistance, this material also exhibits excellent rubber-to-metal adhesion and elasticity. While possessing commendable ozone resistance, caution is advised for application in extreme conditions. This premium Nitrile rubber finds typical use in various applications such as gaskets, bumpers, seals, and more.

Advantages of NBR rollers:

1. Excellent performance

Nitrile Rubber Roller has good oil resistance and aging resistance, the surface of the rubber body is fine and smooth, the rubber body material and the core shaft are firmly bonded.

2. Good stability

With high temperature resistance to acid, alkali salt, fluorocarbon compounds and a variety of strong corrosive additives containing the chemical stability of lubricants and fuel oils.

3. Overall stability

The size of the Nitrile Rubber Roller is strictly controlled, and the size will not change greatly under different temperature and humidity conditions.

Nitrile Rubber Roller are widely used in: machinery, electronics, lithium battery, textile printing and dyeing, leather, printing, wood industry, paper industry, conveyor equipment and other industries。

Advantages of production and technology:

Hai Chang produces Nitrile Rubber Roller to meet various needs of customers, such as: abrasion resistance, hardness, product precision, anti-adhesive product structure, anti-tear, anti-static, elasticity, dust-proof, conductive, acid and alkali resistance, high temperature resistance and so on.

Surface molding can be done in a variety of styles:

For example: groove surface, matte surface, mirror surface, rough surface, mesh surface and so on.