- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

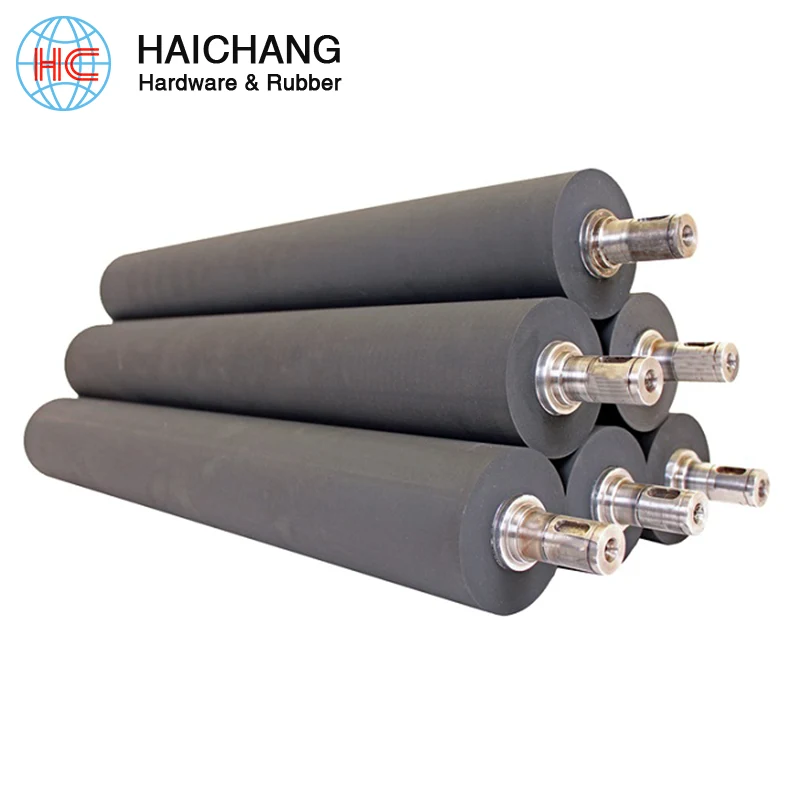

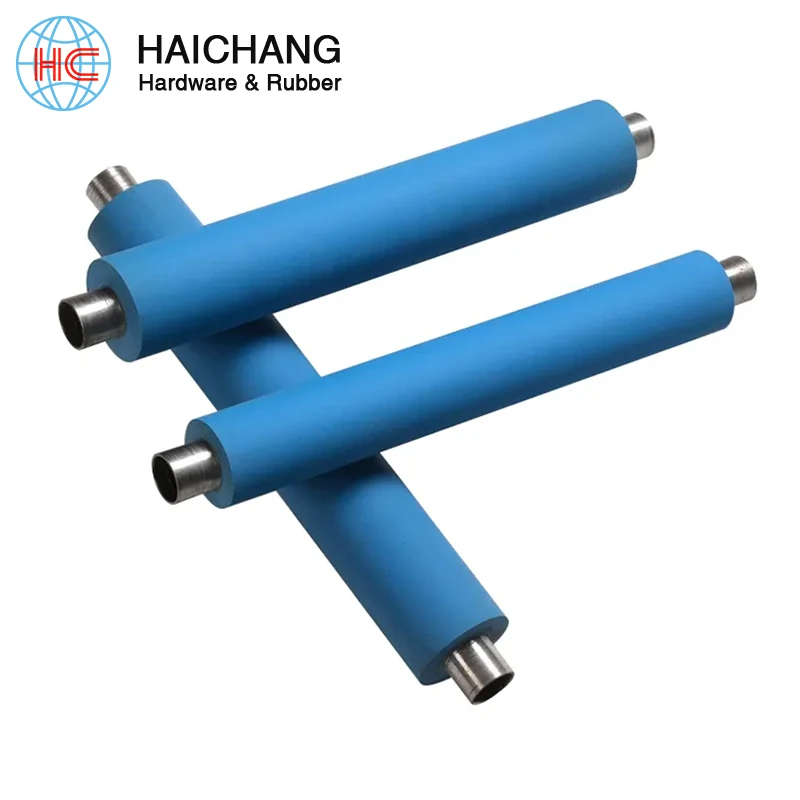

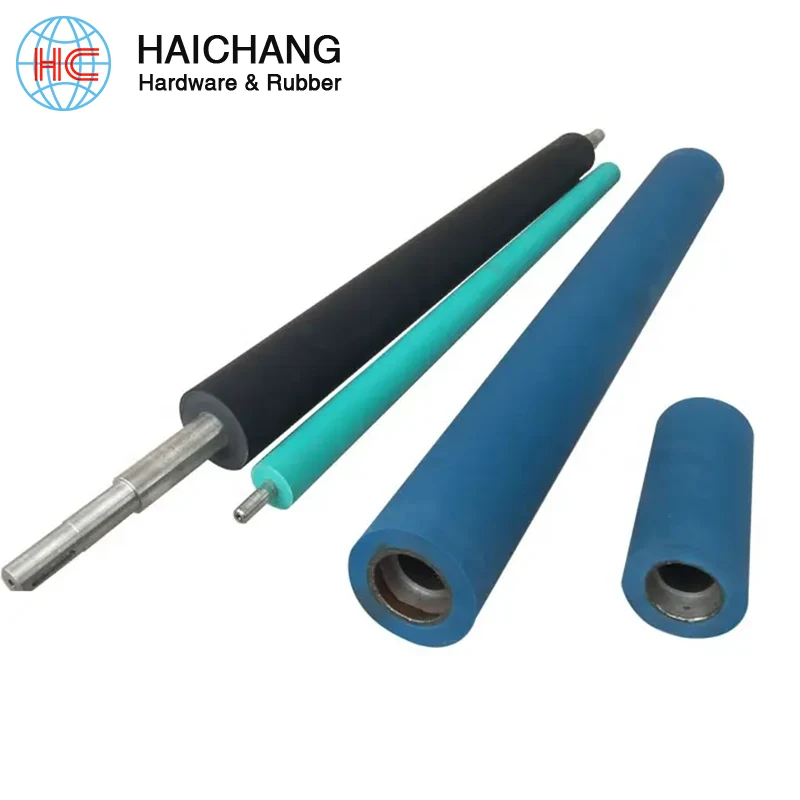

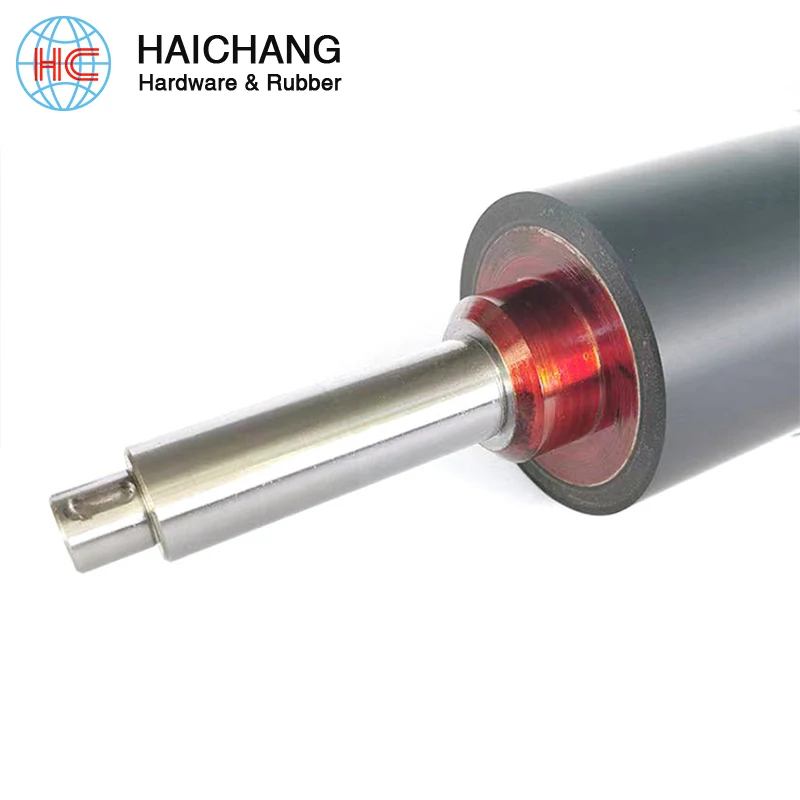

Plate Processor Rubber Roller

Haichang is a professional leader China Plate Processor Rubber Roller manufacturer with high quality and reasonable price. Our Plate Processor Rubber Rollers are designed for optimal performance in plate processing applications. These specialized rollers are crafted to meet the demanding requirements of plate processors, ensuring efficiency and precision in the printing process. With a focus on quality and functionality, our Plate Processor Rubber Rollers are engineered to deliver reliable and consistent results for your printing needs. Welcome to contact us.

Send Inquiry

You can rest assured to buy Plate Processor Rubber Roller from our factory. Printing rubber rollers are used in a wide range of scenarios: Can be used in printers, copiers, punch presses and other rollers above the injection molding silicone / printing and dyeing / paper / printing / environmental protection / plastics and other tanning industry rollers; PCB / LCD process / light guide film / soft sheet precision printing.

In addition to plate processor rollers used in the printing industry, Haichang Plate Processor Rubber Rollers are also widely used in metallurgical manufacturing, coal, wood processing, chemical fiber, textile, automation equipment, electronics, construction industry, aviation, medical equipment, machinery and other industries.

Some of the specific features of our range are as follows:

Precision engineered

Great finish

Accurate dimensions

Varied shapes and sizes

Precautions for use/installation of Plate Processor Rubber Roller

1, when handling and moving, must lift, shaft, to prevent the rubber surface knocking, touching, scratching.

2, the new roller is not used temporarily, please do not remove the wrapping paper, the wrapping paper can play a protective role.

3, super standard period of storage of the rubber roller, should be checked before use of the rubber roller without problems can be used on the machine.

4, the Plate Processor Rubber Roller storage environment and rubber blanket, should choose a cool, dry, ventilated place, the temperature is maintained at 20 ~ 25 ° C, the relative humidity is maintained at 60% ~ 70%, to avoid direct sunlight, preferably backlit places or warehouses dark room.

5, should be away from high temperature, heat and radioactive sources, avoid storage with acid, alkali, oil and sharp hard substances.

6, the Plate Processor Rubber Roller should be vertical or horizontal rack, it is best to use a special rack placed horizontally, the rubber head should be racked on the rack, support the two sides of the shaft shoulder, and keep the rubber roller parallel to the ground, it is strictly prohibited to the rubber surface of the mutual stacking, extrusion, or contact with other items, in order to prevent deformation of the rubber surface under pressure, adhesion, and, at the same time, do not remove the wrapping paper before use.

7, the Plate Processor Rubber Roller should not be stored in the neighboring large electric motors, generators. Because a large amount of ozone produced by these equipments will make the surface of the rubber roller aging and cracking.