- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

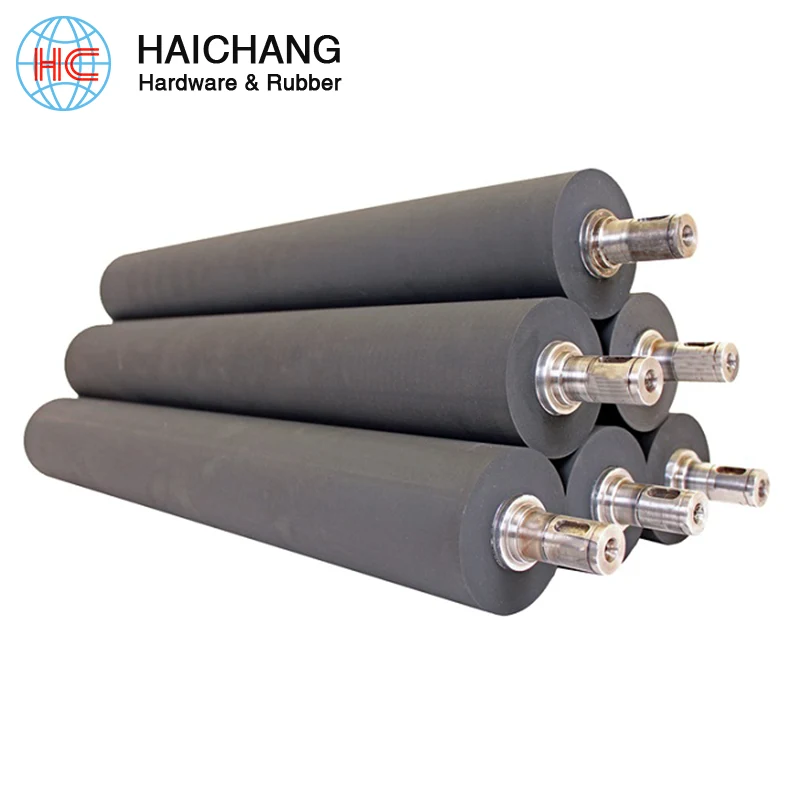

Coating Machine Rubber Roller

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Coating Machine Rubber Roller. These rubber rollers are designed to deliver outstanding coating results. The specialized construction ensures a smooth and uniform application of coatings on various surfaces.

Send Inquiry

Coating machine rubber roller product introduction:

Crafted from high-quality rubber compounds, these rollers exhibit excellent durability and resilience. They can withstand the rigors of coating processes, ensuring long-lasting performance. Coating Rubber Roller / Applicator Roller,high quality raw materials by , guarantees excellent mechanical properties with lowest abrasion and high resistivity, equivalent to Industrial standards. It helps the customers improve their efficiency in their procedures and products.

Why choose Haichang Coating Machine Rubber Roller?

Made of high-quality materials and in line with industry standards, no corners are cut.

Quality craftsmanship

The surface treatment is flat, smooth and burr-free, and the workmanship is careful, beautiful and practical.

Support customization

Home supply complete specifications and can be customized according to customer requirements

Strict quality inspection

Strictly inspect products and control every step of the process to ensure product quality.

Precautions for use/installation of rubber rollers

1, when handling and moving, must lift, shaft, to prevent the rubber surface knocking, touching, scratching.

2, the new roller is not used temporarily, please do not remove the wrapping paper, the wrapping paper can play a protective role.

3, super standard period of storage of the rubber roller, should be checked before use of the rubber roller without problems can be used on the machine.

4, the Coating Machine Rubber Roller storage environment and rubber blanket, should choose a cool, dry, ventilated place, the temperature is maintained at 20 ~ 25 ° C, the relative humidity is maintained at 60% ~ 70%, to avoid direct sunlight, preferably backlit places or warehouses dark room.

5, Coating Machine Rubber Roller should be away from high temperature, heat and radioactive sources, avoid storage with acid, alkali, oil and sharp hard substances.

6, the rubber roller should be vertical or horizontal rack, it is best to use a special rack placed horizontally, the rubber head should be racked on the rack, support the two sides of the shaft shoulder, and keep the rubber roller parallel to the ground, it is strictly prohibited to the rubber surface of the mutual stacking, extrusion, or contact with other items, in order to prevent deformation of the rubber surface under pressure, adhesion, and, at the same time, do not remove the wrapping paper before use.

7, the Coating Machine Rubber Roller should not be stored in the neighboring large electric motors, generators. Because a large amount of ozone produced by these equipments will make the surface of the rubber roller aging and cracking.