- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

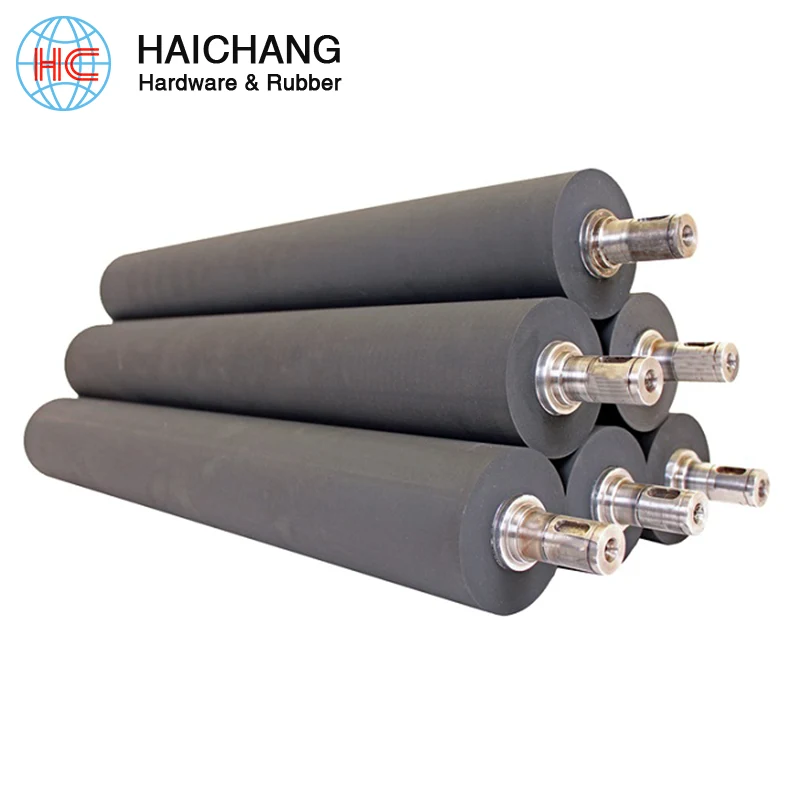

Lamination Rubber Rollers

As the professional manufacturer, we would like to provide you Lamination Rubber Rollers. Since lamination requires heat in order to properly bond the two materials, laminating rolls must be fabricated from materials that are capable of high heat-resistance such as silicone, which is capable of withstanding temperatures of up to 500º F (260° C). Additional elastomeric materials capable of withstanding high temperatures include fluorocarbons, EPDM, neoprene, butyl rubber, nitrile butadiene (NBR) and chlorinated polyethylene.

Send Inquiry

Lamination Rubber Rollers are essential in a broad spectrum of industries, including marine products manufacturing, for lamination of the underside of offshore vessels; woodworking, for the lamination of table tops, chairs and other pieces of furniture; industrial manufacturing, for processing and assembly equipment such as web converting machinery; and printing, for the lamination of important documents, identification cards and other types of paper requiring a protective outer coating. Often, laminating rolls are constructed with a metallic core, such as aluminum, steel or stainless steel, with the elastomeric material bonded onto the core through a rubber-to-metal bonding process.

The rubber-to-metal bonding process involves the rubber, the bonding agents and the substrate. Once the rubber is determined, the bonding agent can be determined, and they generally consist of a polymer-solvent solution, a primer coat based on phenolic-style resins and a top layer of polymers and other materials. To apply the bonding agent, a primer coat must be sprayed over a slightly wider area than the topcoat through the use of a barrel spraying machine. The substrate and the rubber must then be pressed together to enable the bonding to occur.

Once manufactured, for lamination there must typically be three sets of rollers: a drive roller, a guide roller and a laminating roller. There must be a 1:1:1 ratio of these three roller types. The guide roller and the laminating roller rotate in direct correlation to the rotation of the drive roller.

While the drive roller moves the material, the guide roller stretches the material and the laminating roller laminates the material as it is stretched and extruded between the rollers. Lamination offers several benefits, including enhanced color and contrast of materials, protection from abrasion and increased material strength.

Why Choose Us?

1.20 years of experience in Industrial Rubber Rollers production and R&D

2.Professional team service

3.We are manufacturers without middlemen trading competitive price

4.Customized service according to your requirements

5.Advanced testing and manufacturing equipment

6.Short lead time

7.24 hours after-sales service